HP-H(H)KC Series High Efficient Preheating Kneading Cooling System for Special Graphite

HP-H(H)KC Series High Efficient Preheating Kneading Cooling System is mainly used in the preparation of paste in carbon industry, for the production of prebaked anode, aluminum cathode, graphite electrode, special graphite and other products. After the aggregate is heated to the specified process temperature in the preheating machine, it enters the kneading machine to complete the kneading of the dry material and the binder pitch, forming paste with good plasticity, and the paste enters the cooling machine to be cooled to the specified forming temperature.

HP-H(H)KC High Efficient Preheating Kneading Cooling System is equipped with new efficient high-temperature tank, high-efficient high-temperature mixing blade, safety monitoring system of rotary joint, new sealing device of mixing blade shaft end, safety protection device of mixing blade, real-time monitoring system of mixing blade, pitch uniform feeding device, transmission system with strong bearing capacity and reliable operation, convenient replacement of lining plate, accurate temperature measuring device, etc, to ensure the operation of equipment is efficient, stable and reliable.

Technical performance

After surface treatment, the surface roughness of the curved section and surface of the mixing blade reaches 0.1, the mixing and cooling materials are divergent, not easy to stick to the mixing blade, and the service life of the mixing blade is 20 years.

It adopts new extended high-efficiency tank technology, high-efficiency high-temperature tank patent technology, mixing blade heating patent technology, new mixing blade heating patent technology and full-area heating patented technology. The dry material has fast heating speed and high heating efficiency.

The dry mixing preheating part adopts tangent, different speed and radius dry material mixing and heating technology to mix the materials evenly.

The paste kneading adopts intersectant synchronous mixing blade, overlying mixing technology. The materials are kneaded evenly without kneading blind angle and block raw material.

Equipped with dust collector to collect the dust released during dry material feeding in dry mixing process and protect the environment.The collected dust will return automatically and continue to participate in the dry mixing process to ensure the balance of materials and product quality.

The patented technology of new thermosensitive temperature measurement assembly is adopted, with accurate temperature measurement and temperature measurement error of ± 2 ℃.

The patented combined overlapping metal ring seal technology is adopted to ensure that there is no carbon powder leakage at the shaft end of the mixing blade.

The tank is made of low-alloy high-strength steel plate Q460D. The internal surface of the tank is treated with a surface roughness of 0.1. The materials is not easy to stick to the tank . The service life of the tank is 20 years.

Wear resistant welding layer is overlaid on the surface of the mixing blade, and the service life of the mixing blade is 20 years.

The unloading system adopts hydraulic turnover to lock the unloading gate to ensure no material leakage.The tank and discharge gate shall not leak carbon fine powder.

The mixing blade bearing is designed to be movable to prevent the mixing blade from being heated, extended and stuck;The mixing blade is equipped with bi-directional thrust bearing to prevent the mixing blade from grinding the tank..

The tank has a separate structure, and a feeding port and a dust collection port are reserved on the upper cover.

Equipped with real-time monitoring system for main bearing temperature of main engine, alarm immediately in case of abnormality.The main shaft bearing cooling and monitoring system is equipped to cool the main shaft bearing in real time, monitor the cooling medium temperature, flow and other parameters in real time, and give an alarm immediately in case of abnormality.Ensure the safe, reliable and stable operation of the spindle-bearing system in a high temperature environment.

Equipped with mixing blades safety protection device.Cut off the power immediately to protect the mixing blade from damage in case of overloading. After the load returns to normal, directly start the main motor, the safety protection device automatically combines and restores the power, and the system returns to normal operation.

Technical Parameters

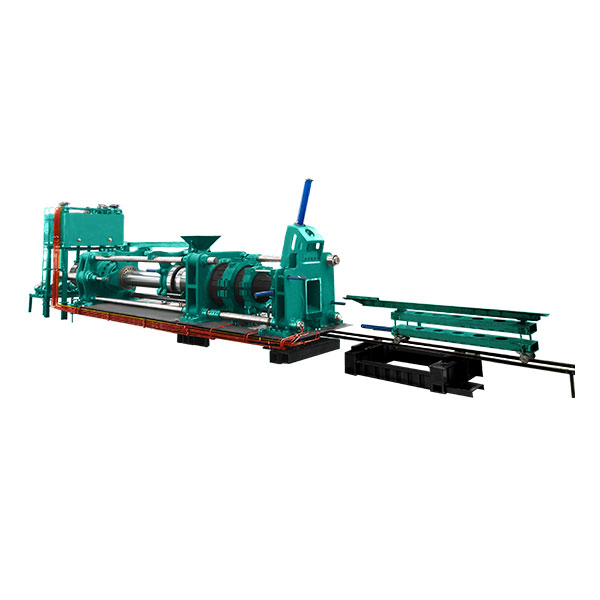

| Special graphite dry material preheating machine | HP-DMH(H)600-SG | HP-DMH(H)2000-SG | HP-DMH(H)3000-SG |

| Rated Volume (L) | 600 | 2000 | 3000 |

| Maximum Volume (L) | 1150 | 3680 | 3900 |

| Revolution of Mixing Blade (RPM) | 16/13 | 12/15 | 12/15 |

| Heating Method | Heat transfer oil | Heat transfer oil | Heat transfer oil |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

| Kneading Method | Tangent different velocity radius | Different tangent radius | Tangent different velocity radius |

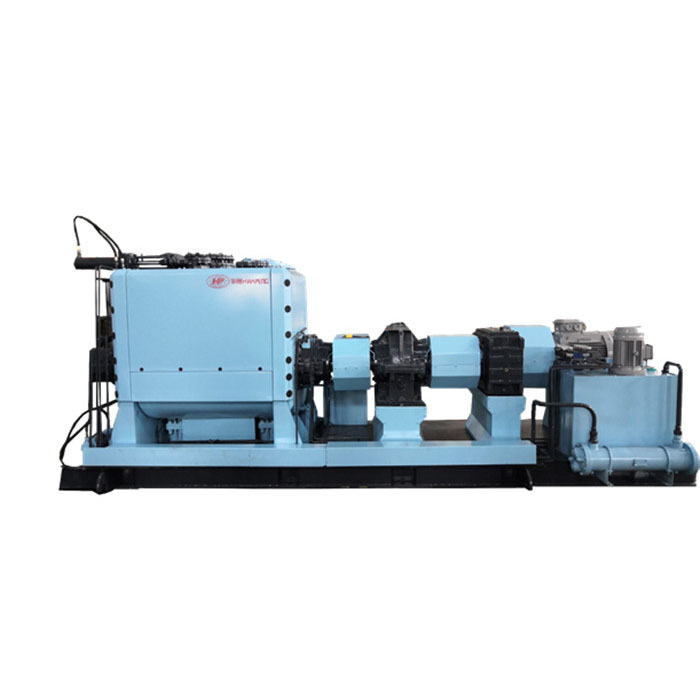

| Special Graphite Kneader | HP-CPK600-SG | HP-CPK2000-SG | HP-CPK3000-SG |

| Rated Volume (L) | 600 | 2000 | 3000 |

| Maximum Volume (L) | 1000 | 3450 | 4800 |

| Kneading Method | Intersection same velocity superradius | Intersection same velocity superradius | Intersection same velocity superradius |

| Revolution of Mixing Blade (RPM) | 16 ~ 32 (adjustable) | 16 ~ 32 (adjustable) | 12 ~ 18 (adjustable) |

| Heating Method | Heat transfer oil | Heat transfer oil | Heat transfer oil |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

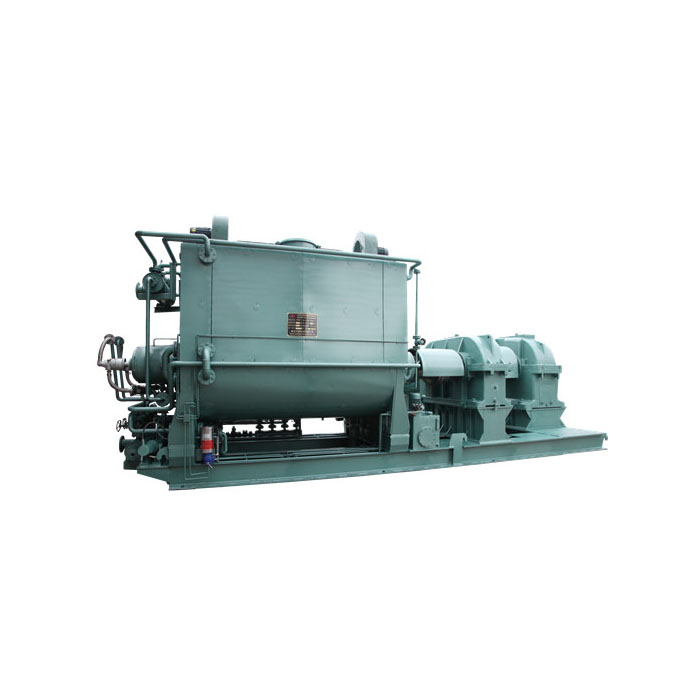

| Special Graphite Paste Kneading Cooler | HP-PKC600-SG | HP-PKC2000-SG | HP-PKC3000-SG |

| Rated Volume (L) | 600 | 2000 | 3000 |

| Maximum Volume (L) | 1000 | 3850 | 5200 |

| Revolution of Mixing Blade (RPM) | 5 ~ 10 (adjustable) | 5 ~ 10 (adjustable) | 5 ~ 10 (adjustable) |

| Mixing Method | Intersection same velocity superradius | Intersection same velocity superradius | Intersection same velocity superradius |

| Cooling Method | cooling water | cooling water | cooling water |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |