AIV-CS Baked Anode Cleaning Robot

Baked Anode Cleaning Robot

Baked anode cleaning robot is an artificial intelligent polishing robot which is developed by our company aiming at harsh work environment during cleaning and polishing of baked anodes for aluminum smelters.

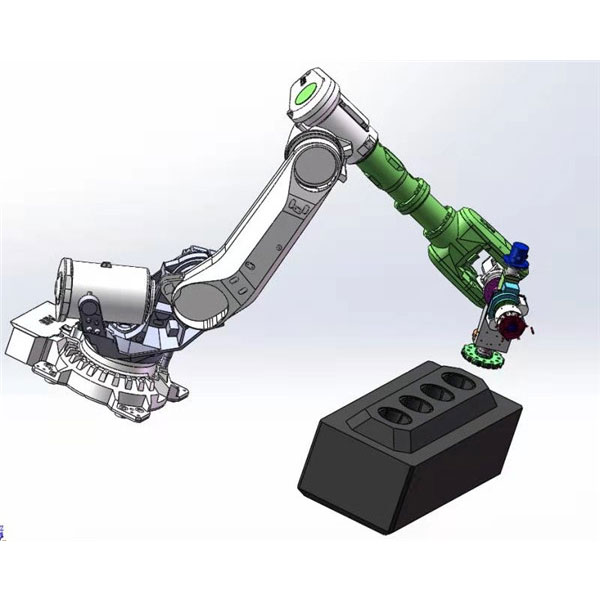

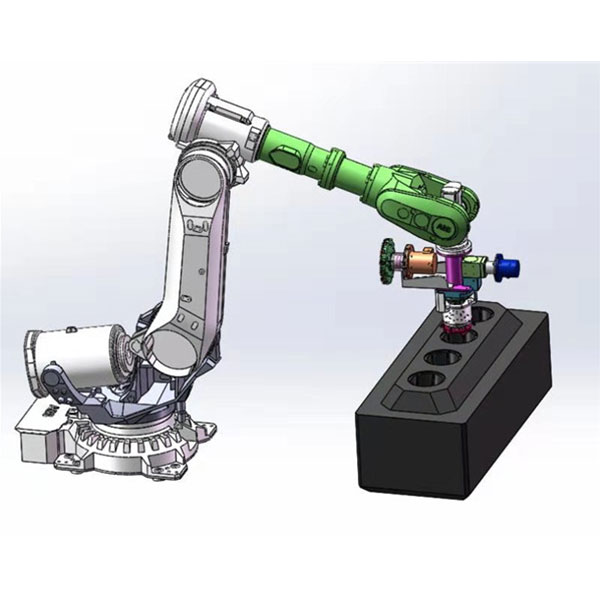

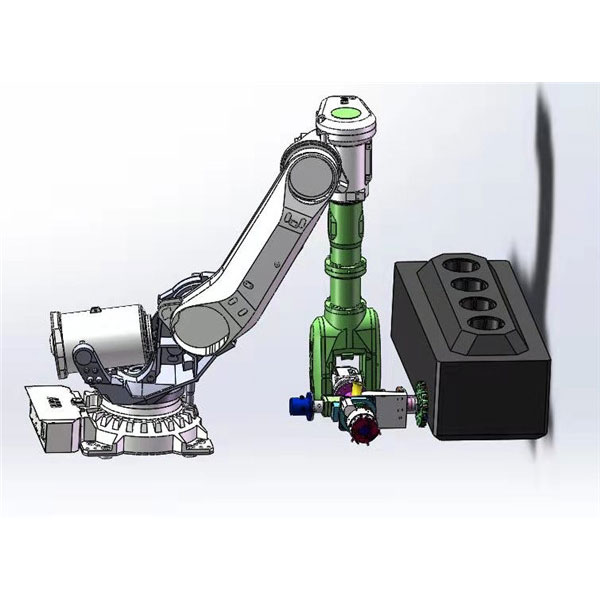

Deep learning camera will take photos of anode blocks, after cloud processing and 3D imaging, it will send the three-dimensional coordinates of anode blocks to the robot, then the robot will clean anode block surfaces, stub holes and flutes, dust collecting device will take packing coke out while the robot cleaning stub holes.

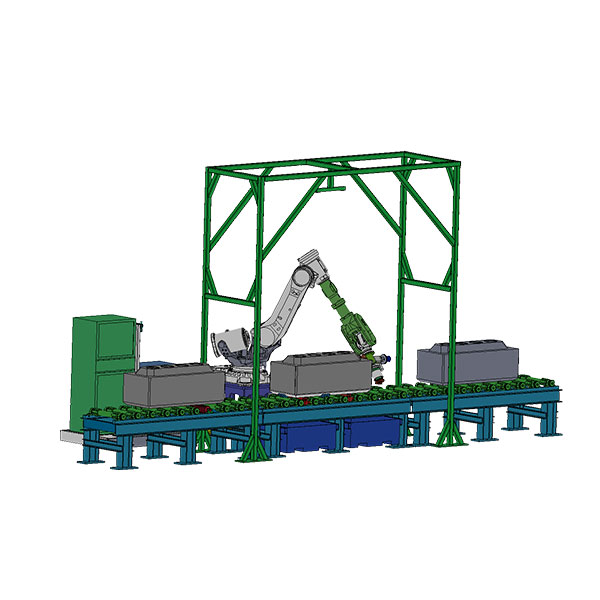

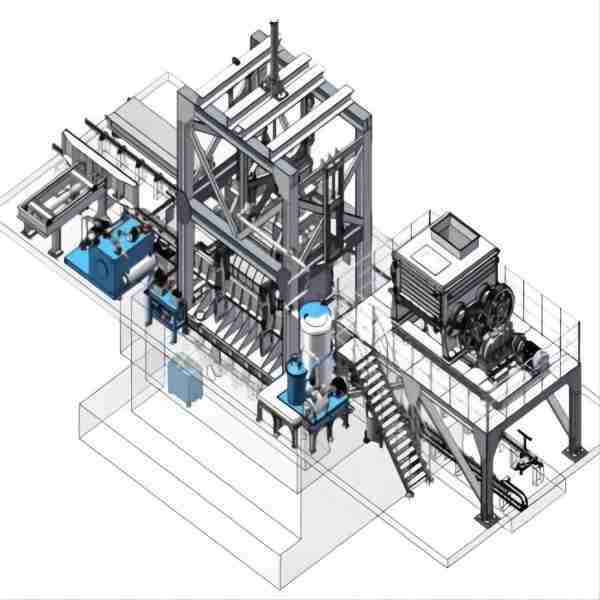

System configuration

1 Visual shaping system and software

2 Robot and polishing system

3 Dust collecting and electric control system

4 Anode blocks conveying system

Advantages

1.Intelligent real-time sense

The deep learning algorithm independently researched and developed by our company can sense the position of carbon blocks and moving status of the robot at real-time to adjust polishing actions of the robot.

2.Flexible polishing

The brush in floating milling cutter allows the robot to remove packing coke which is slightly stick on the surface of anode blocks without hurting the carbon blocks.

3.Clean without dust

Dust collecting device can take away the packing coke which is stripped from anode blocks and manual cleaning is not needed.

4.Thorough cleaning of flutes in stub holes

Flutes in stub holes are cleaned by milling cutter which can thoroughly clean packing coke stick inside.

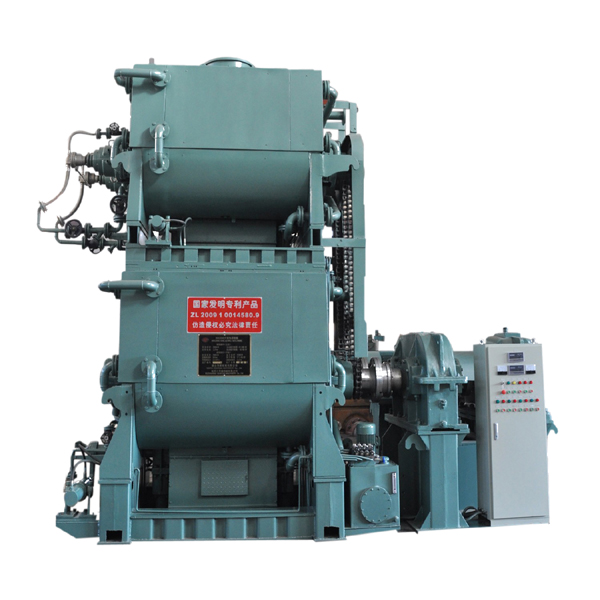

Stub hole cleaning technologies

1.Flute cleaning milling cutter set

The cleaning of the chute of the stub hole is completed by a high-speed rotating milling cutter, which can clean up packing coke.

No impact force, effectively avoid the impact damage of the manipulator and ensure the operation accuracy of the manipulator.

2.Intelligent sensing mechanism

The spiral scraper is equipped with a speed sensor. When there is iron in the

packing coke, the speed will decrease rapidly, so as to stop grinding and give an

alarm.

3.Stub hole suction mechanism

The spiral scraper can scrape off the packing coke in the stub hole, and the packing

coke is sucked away by the suction pipe in the middle.

Anode surface cleaning technologies

1.Force controlled floating cleaning mechanism

The pressing force is realized by the cylinder, which is controlled by the piezoelectric proportional valve, with high sensitivity and fast response.

2.Ball transmission mechanism

The power transmission adopts ball transmission, with high pressure control precision, small rotating friction and no tool clamping.

3.Cutter head angle floating

The cutter head floats in the angular direction to make the cutter head fit closely with the work piece.

4.Acquisition and intelligent control

With speed and displacement sensors, real-time feedback signals are provided during the working process, so as to change various grinding parameters in real time to

achieve the best cleaning effect.

5.Self leaning function

The program has self-learning function. The more data accumulated in the database, the better the grinding effect will be.

6.Cutter design and material selection

The cutter head is made of Cr12 alloy steel, which is firm and durable. The blade tip is finished tungsten steel blade, which is easy to replace.