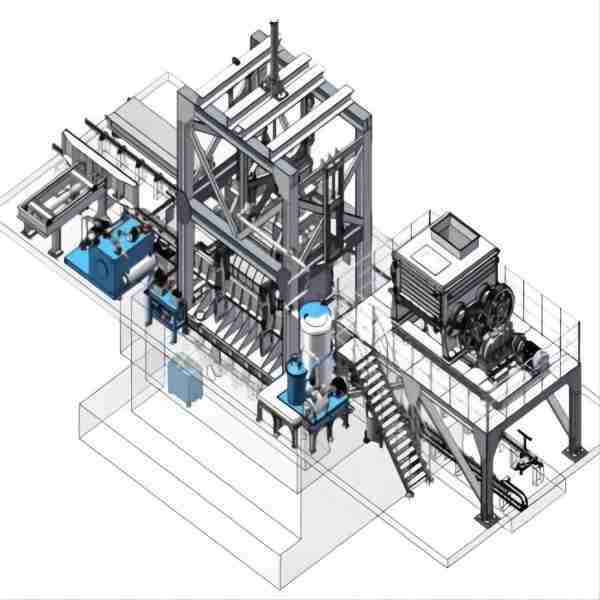

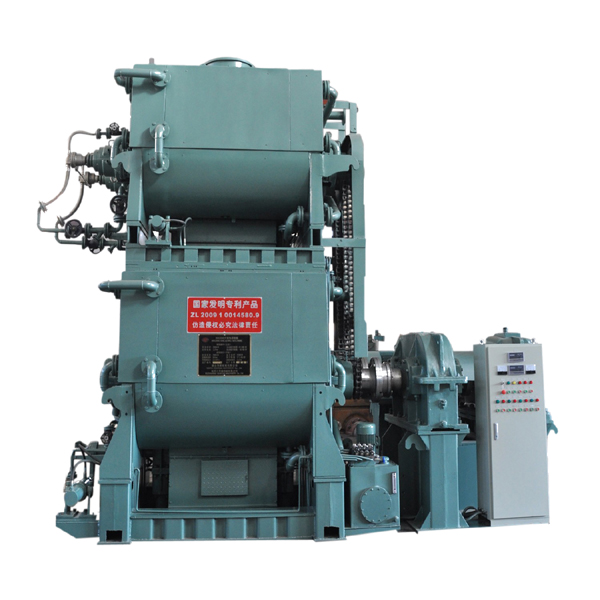

HP-EVC1500HP-EVC1500 SERIES AIRBAG PRESSURIZATION VACUUM VIBRATION FORMING MACHINE

TECHNICAL PERFORMANCE:

1. Uniform distribution

The uniform distribution system includes: Homogeneous Mixer, Distributing Device, Reciprocating Mold and Automatic Leveling Device.

Set distributing device at the outlet of homogeneous mixer, that the paste is vertically discharged to the mold at a uniform speed through the distributing device. The mobile cart drives the mold to move back and forth at a uniform speed, so that the paste is evenly distributed into the mold in several times according to the required weight, and the automatic leveling device flattens the surface of the paste at the same time. Move the cart to drive the mold back and forth several times until all the required paste with the specified weight enter the mold.

After the above uniform distribution process, the paste in the mold are evenly distributed and the surface of the paste is flat.

2. Vacuum

The vacuuming system includes: vacuum cover, hydraulic lock system, fully sealed mold and vacuum pumping station. Vacuum cover, hydraulic lock system and fully sealed mold ensure overall mold tightness. The vacuum pump station makes the sealed mold reach the required vacuum degree. The absolute value of the relative vacuum degree of the system is greater than 0.09MPa.

3. Airbag damping

The use of airbags vibration damping for the vibration table has good vibration damping performance, which is beneficial to improve the homogeneity of the vibrating carbon block.

4. Airbag pressurization

The flexible pressure of the airbag is adopted to ensure the specific pressure of the carbon block during the vibration process, which is beneficial to improve the bulk density of the carbon block. The airbag has stable vibration damping performance, which is beneficial to improve the homogeneity of the vibrating carbon block. The airbag pressurization method does not increase the mass of the system participating in the vibration with the increase of the pressurized pressure, so it can effectively improve the pressurized specific pressure, effectively utilize the system exciting force, ensure the bulk density and quality of the vibrating carbon block, improve the vibration efficiency and reduce the vibration energy consumption.

5. Forming process

The high-efficiency high-strength homogeneous vibration molding process is controlled by computer software.

High efficiency and high strength homogeneous vibration molding process to ensure product uniformity, improve body density, improve efficiency, computer software automatic control, to ensure that the production process strictly implement the production process requirements, eliminate human instability factors, to ensure product quality stability.