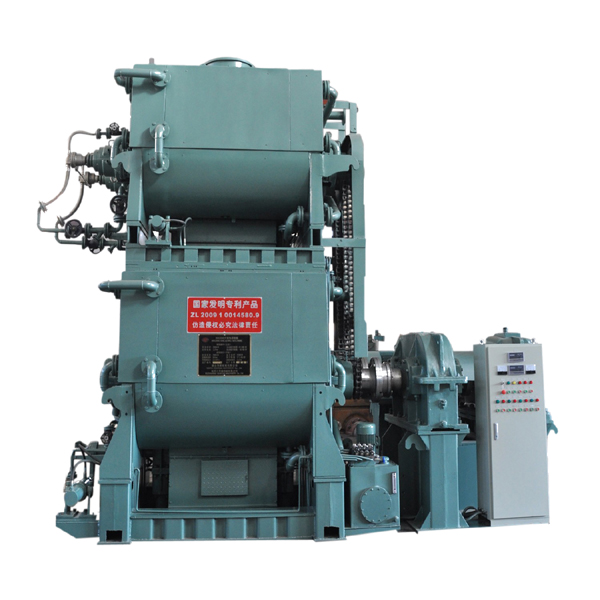

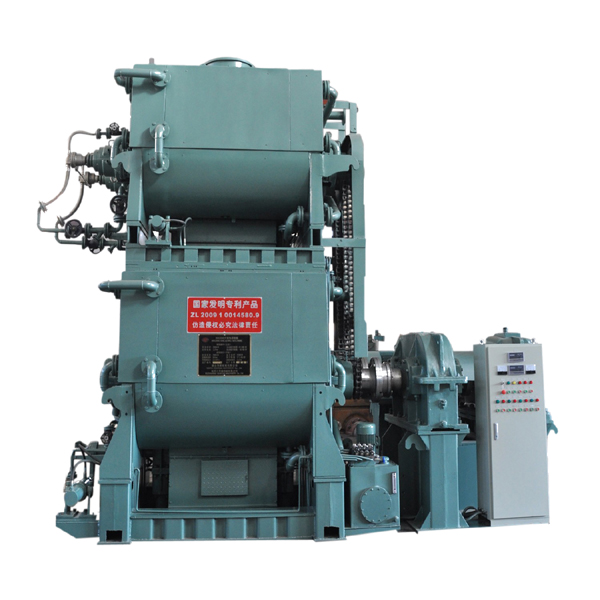

– Hwapeng HP-DHK series Double-layer preheating kneader – Hwapeng

– Hwapeng HP-DHK series Double-layer preheating kneader – Hwapeng Detail:

Technical performance

1.High preheating quality of dry materials

The upper layer adopts tangent, different speed and radius dry material mixing and heating technology.The mixing blade stirs materials and heats the material at the same time, so that the materials can continuously directly contact the heat transfer surface of the equipment to realize efficient heating.The utility model overcomes the defect of low heating efficiency caused by poor thermal conductivity of dry materials when dry materials are heated in a static state.

2.High mixinging quality

The lower layer adopts intersectant synchronous mixing blade, overlying mixing technology introduced from Japan. Mixing blades rotating range exceed the middle of tank which enlarge the actuating area; two mixing blades have the same spiral climbing direction but different rotating direction, one mixing blade pushes material to the middle and the other one pushes to both sides, material flows like“8″ in the tank.

Introduce in the original mixing blade from Japan, the section of mixing blade is elliptic and it pushes material to move along with vertical direction of the elliptic section, squeezing action is intensified, material granules are fully mixed, mixing and kneading effect is strengthened. Elliptic section does not stick to material easily and the surface of mixing blades is free of materials.

3.High efficiency and energy saving

It adopts double-layer preheater and mixer patent technology (Invention patent number: ZL 200910014580.9), double-heating & double-mixing carbon mixer technology (Invention patent number: ZL 200420018997.5), with dry material preheating on upper layer and carbon paste mixing on lower layer at the same time, productivity is improved by 80%.

4.Fast heat transmission and high temperature

It adopts high-efficiency high-temperature tank patent technology (Invention patent No.: ZL 2012 1 0124643.8), new mixing blade patent technology (Invention patent No.: ZL 2016 1 0897074.9, ZL 2016 1 0897263.6), comprehensive heating patent technology, mixing blade heating patent technology, discharge gate heating and seamless fitting technology between lining plate and tank body. Integral heating mixing blade is adopted. The blades, hollow axis and other mixing parts contacting materials heat materials through heat transfer oil.

5.Safety monitoring system of rotating joint and flexible metal tube (optional configuration)

Rotating joint of heat transfer oil is installed with position sensor to monitor displacement of fixed housing of rotating joint and keep communication with central control system at real time. The machine will be stopped immediately and send alarm in case of abnormal conditions. Heat transfer oil inlet and outlet of rotating joint and metal tube are Installed with pressure sensor to monitor tube pressure and communicate with central control system, to prompt system maintenance and alarm pipeline leakage in case of pressure changes.

6.Mixing blade safety monitor system (optional configuration)

Mixing blades adopt special design, position sensor monitors operation of mixing blade at real time and transmits running state of mixing blade to central control system. In case mixing blades are blocked by foreign matters, the machine will stop urgently and send alarms to avoid equipment damage.

7.Guarantee dry material particle size distribution

Use special equipment to process inner diameter of tank and bearing hole of tank end plate, equipment machining precision is high and it guarantees gap requirement between mixing blade and tank and prevents particles from grinding during dry mixing and heating.

8.Uniform pitch distribution

Pitch distribution device is mounted on cover to add pitch into the tank uniformly through multiple points, inclusion of dry material block in paste is avoided. The device is heated by heat transfer oil to avoid solidified pitch blocking the device.

9.Accurate temperature measurement

New temperature measurement technology (Patent No.: ZL 2014 2 0490132.2) is adopted to improve the thermo-responsive and anti-interference of temperature measuring performance.

10.Perfect air-tightness

Adopt combined overlapping metal ring to from multi-channel sealing (Invention patent No.: ZL 2014 2 0490187.3) to guarantee no carbon powder leakage form shaft end of the mixing blade; Hydraulic rotary lock discharge gate has excellent air-tightness, the sealing surface of which never wears out so that air-tightness is reliable and no material leaks from discharge gate.

11.PLC full automatic control

PLC control and internet communication is adopted to measure, display and transmit equipment running and status parameters at real time (optional configuration). Three kinds of operation mode—internet automatic, single machine automatic and manual–guarantee the machine itself can run automatically no matter if upstream and downstream machines are automatic(optional configuration).

12.High wear-resistance

Mixing blade is surface welded with wear-resistant layers with the rigidity up to HRC60-65, and service life of mixing blade is 20 years. Tank lining plates use new type wear-resistant manganese steel material with excellent strength after thermal treatment. Service life of lining plates to produce anode is 15 years and it is 1 year to produce cathode and carbon electrodes.

13.Reliable bearing structure of mixing blade

Mixing blade shaft adopts self-aligning roller bearing and double-direction thrust bearing design which overcomes axial force of mixing blade and prevents mixing blades from axial shifting and service life of bearing is longer. Bearing structure is fixed on one side and movable on the other side, which eliminates influence of thermal expansion and prevents mixing blade from seizing after it is heated by heat transfer oil.

14.Full automatic lubrication system with real time monitoring (optional configuration)

It adopts full automatic lubrication system, lubrication interval and lasting time can be adjusted. Lubrication station has pressure sensor to monitor work state of main station of automatic lubrication system at real time, and to send alarm in case of abnormal conditions.

Each lubrication point has automatic reset pressure slide valve and position sensor monitoring work state of each lubrication point and automatically sending out system maintenance prompt and malfunction alarm.

15.Low noise

It is processed with special equipment, to get good concentricity, easy operation and long service life,

And the operating noise of the entire machine is lower than 80 dB.

16.Reliable operation of transmission system

It adopts hard teeth reduction gearbox and synchronous gearbox split structure with full lubrication and reliable operation. Hard teeth reduction gear, bearing capacity of which is 3 times of common one, together with gear Coupling, guarantees high bearing capacity of transmission system. Hydraulic clutch can adjust transmitted torque according to the load to provide overload protection, and allow the machine to restart with load in case of some special occasions (such as restart after stopping during running).

17.Easy maintenance

It adopts double-layer preheater and mixer patent technology (Invention patent number: ZL 200910014580.9), the equipment has traction and sliding device to draw “upper tank” moving on “lower tank” to leave maintenance space for maintenance of lower layer. Tank end plate and tank adopt open structure, it is separated into upper and lower parts at the position of mixing blade axial line, together with fine machining and enclosed treatment, installation precision and tank airtightness are guaranteed.

18.Fast discharging and no material residue

Mixing blade pushes materials spirally to discharge material fast and completely from bottom open discharge gate without residue left.

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for – Hwapeng HP-DHK series Double-layer preheating kneader – Hwapeng , The product will supply to all over the world, such as: Pakistan, Uruguay, Gabon, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.