On the afternoon of August 1, 2023, the Vietnamese Provincial People’s Committee held a ceremony to issue an investment registration certificate for the Vietnam Innovation Precision Co., LTD project. Deputy Secretary of the Provincial Party Committee and Chairman of the Provincial People’s Committee Nguyen Duc Trong attended the ceremony.

Investor Innovation Metal (China) Greenwich Management Co., LTD. ‘s Innovation Precision Vietnam Co., Ltd. has a total investment of 165 million US dollars and employs about 1,500 highly qualified employees. The products and services provided by the project include: aluminum alloy production for 3C consumer electronics manufacturing; Manufacturing various aluminum alloy castings and casting parts for the electronic product manufacturing industry; Forging, stamping, pressing and rolling metal; Manufacturing advanced machined aluminum components to support the electronics manufacturing industry.

Innovation Metal is the first province to expand investment in the Vietnamese market. When the project is put into production together with the foreign investment projects currently underway in Nghe An province, it will form an ecosystem of electronics manufacturing, green energy production, which will be a very efficient ecosystem and complete the supply chain of Nghe An Province. Electronic manufacturing, green energy product production, forming an electronic industry ecosystem, green industry.

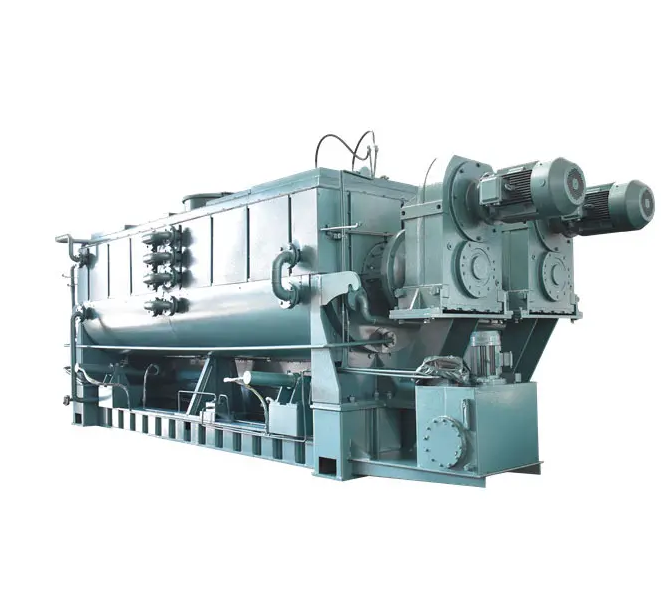

Innovation Metal is also a loyal user of Hwapeng, using Hwapeng’s product HP-DMH Series Dry Material Preheater. HP-DMH Series Dry Material Preheater adopts tangent and differential mixing blade dry material mixing and heating technology, by which materials constantly contact heat transmission surface of equipment directly to realize efficient mixing and heating. Fast heat transmission and high temperature,it adopts efficient high temperature tank patent technology, new type mixing blade patent technology, overall heating patent technology, mixing blade heating patent technology, discharge gate heating technology lining plate and tank seamless fitting technology. Guarantee dry material particle size proportion,it uses special equipment to process the inner diameter of tank and bearing hole of tank end plate, the high machining precision guarantees gap requirement between mixing blade and tank and prevents particles from grinding during mixing and heating. Temperature measurement is accurate,it adopts new temperature measuring technology to improve temperature measuring performance of thermo-responsive and anti-interference. Perfect air tightness,it adopts combined overlapping metal ring to form multiple sealing to guarantee no carbon powder leakage from shaft end of mixing blade; Hydraulic rotary lock discharge gate has excellent air tightness, sealing surface of which will never wear out that air tightness is reliable with no material leakage from discharge gate.

Post time: Aug-05-2023