The project is located in Manpawa, Kalimantan, Indonesia. Chinalco International Engineering Co., Ltd. is the lead party and PT.PP. (Persero) Tbk Company formed a consortium as the EPC general contractor to build a new Indonesian metallurgical grade alumina project with an annual output of 1 million tons (expandable). Chinalco International Engineering Co., Ltd. is responsible for the overall project design, main equipment procurement, part of the construction, commissioning and performance to meet the production standards, and PT. PP.(Persero) Tbk company shall undertake part of the construction and installation work according to the local law requirements of the project.

The overall construction scale of the project is 2000kt/a metallurgical grade alumina project, which is constructed in two phases, of which the construction scale of the first phase project is 1000kt/a metallurgical grade alumina, and the second phase project continues to build 1000kt/a metallurgical grade alumina. The self-provided thermal power plant is located in the aluminum oxide plant area, as a supporting project of the first 1000kt/a alumina project, to provide steam and power supply for the alumina production system, and the power supply adopts the mode of isolated network operation, and is not connected to the external power grid. The self-contained thermal power plant is to be equipped with 3 boilers and 3 turbine-generating units, as well as all necessary auxiliary facilities. At the same time, in accordance with the requirements of the second phase of the construction of 1000kt/a metallurgical grade alumina project, the construction land and facilities of the second phase of the self-provided thermal power plant are planned and reserved. The total contract value of the project is approximately RMB 4.925 billion.

Chinalco Group is a loyal user of Hwapeng, using a lot of equipment produced by Hwapeng, Hwapeng research and development of vibration molding machine, in the production of pre-baked anode performance is particularly good. Users use Hwapeng preheating machine, kneading machine and vibration forming machine to produce pre-baked anode, the products are exported to the United States, Germany, Norway, Sweden, Russia, Kazakhstan, India and other overseas markets, for many years by Rio Tinto as a qualified supplier, good products and services have won the praise of the general users.

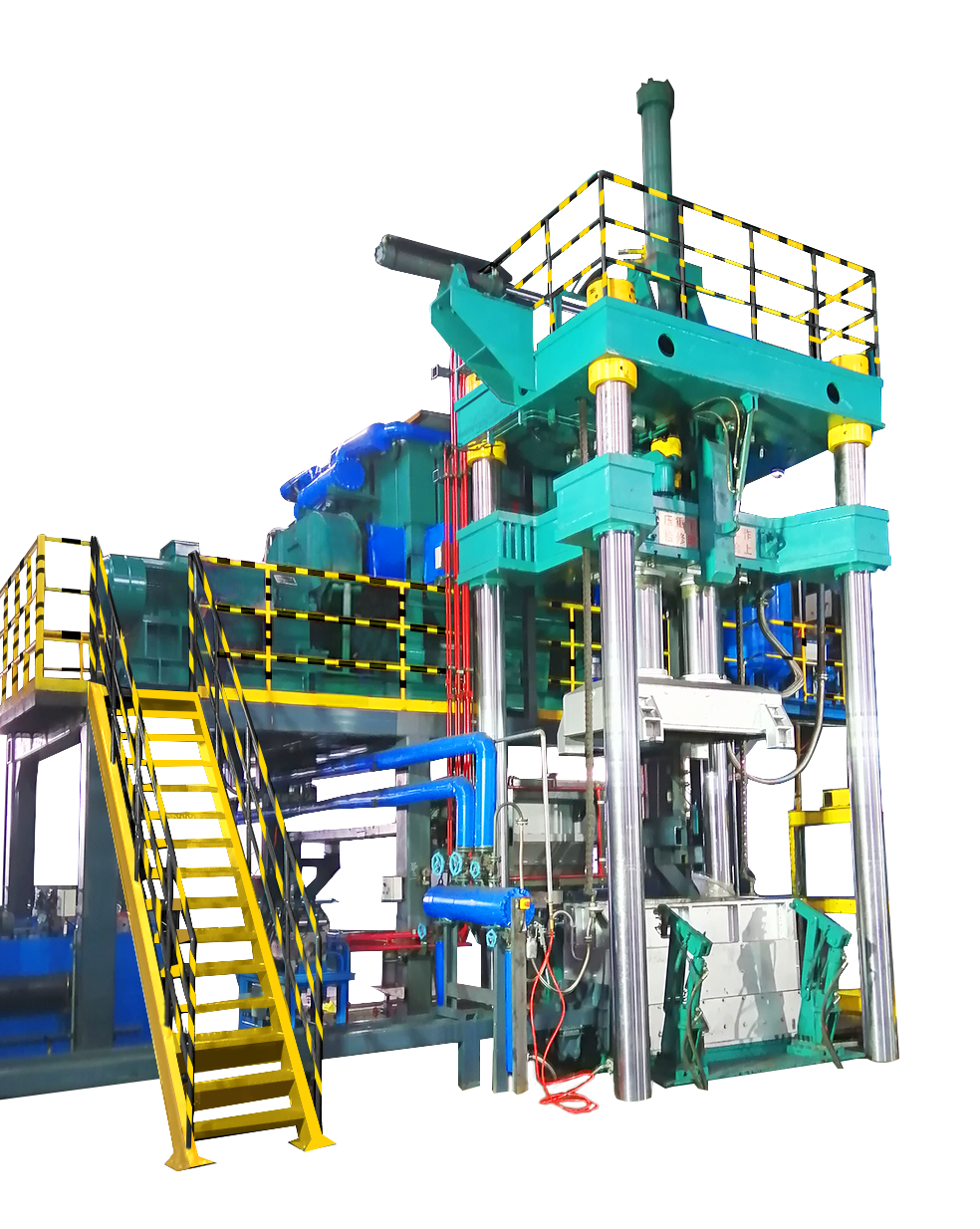

The HP-EVC series vacuum vibrocompactor for green anode has excellent four-column guiding system, vibration forming system, hydraulic system, vacuum system and automatic measuring and detecting system guarantee powerful and stable forming capacity, green anodes produced have the same height at four corners, high density, there is no internal cracks, baked anodes have outstanding performance in cells, HP-EVC Series Vibrocompactor is first class viabration forming machine for green anodes in China.

The technical performance of the HP-EVC Series Vacuum Vibrocompactor for Green Anode are four-column guiding structure, constant pressing pressure, software control technology, vacuum technology, excellent forming process, accurate height measurement of anode blocks, accurate material measurement, high amplitude modulation, reliable vibration, safe, reliable and low noise etc.

Post time: Aug-19-2023