On October 18, Xingqing Customs, a branch of Yinchuan Customs, issued an RCEP certificate of origin for a batch of electrode paste exported by a new material technology company in Ningxia, with which the company is expected to enjoy a tariff discount of about 2,000 yuan. The company mainly produces silicon calcium alloy, silicon magnesium alloy, electrode paste and other products, with the certificate of origin issued by the customs, export products can enjoy tariff preferences. According to Yinchuan Customs statistics, in the first three quarters, Ningxia’s import and export value to other member countries of the Regional Comprehensive Economic Partnership Agreement (RCEP) reached 5.054 billion yuan, an increase of 4.92% year-on-year, accounting for 32.46% of the total import and export trade value of the region. Among them, the import and export to ASEAN was 2.7 billion yuan, an increase of 49.6%

The most obvious dividend brought by RCEP is tax reduction, and the policy dividend released has become an important driving force for Ningxia to expand its export-oriented economy and achieve a higher level of opening-up and development. The most obvious benefits are machinery manufacturing, clean energy and other industries and the upstream and downstream industrial chain of processing of characteristic agricultural and food products, at the same time, the enthusiasm of export-oriented enterprises in our region is high, and cross-border e-commerce trade has been accelerated. The latest data from Yinchuan Customs show that in the first three quarters, Ningxia enterprises enjoyed RCEP tariff concessions for import and export goods worth 505 million yuan. Among them, 8 enterprises enjoy the fruits of RCEP tariff reduction imported goods, enjoying the value of imported goods reached 107 million yuan, and the tax reduction was about 3.546 million yuan, mainly enjoying the import goods of inorganic oxides, catalysts, alloy steel and machine parts; Forty-one enterprises benefited from 398 million yuan of exports under RCEP, and enjoyed tariff concessions of about RMB130,29,600 from other members.

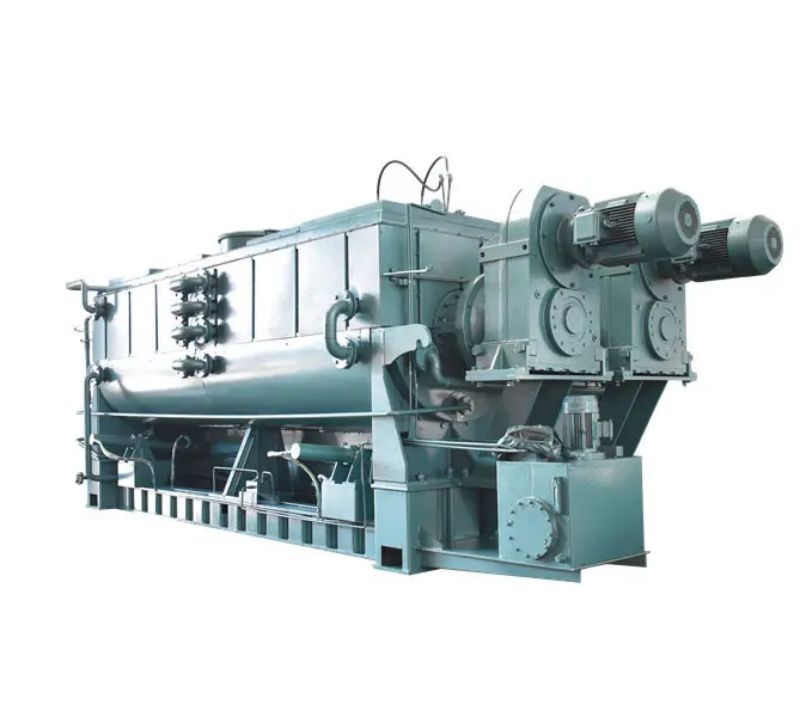

HP-DMH(H) Series High Efficient Dry Material Preheater and HP-CPK Series Carbon Paste Kneader produced by Shandong Hwapeng Precision Machinery Co., Ltd. has excellent performance in the production of electrode paste products. HP-DMH(H) Series High Efficient Dry Material Preheater adopts tangent and differential mixing blade dry material mixing and heating technology, by which materials constantly contact heat transmission surface of equipment directly to realize efficient mixing and heating. Fast heat transmission and high temperature,it adopts efficient high temperature tank patent technology, new type mixing blade patent technology, overall heating patent technology, mixing blade heating patent technology, discharge gate heating technology lining plate and tank seamless fitting technology. Guarantee dry material particle size proportion,it uses special equipment to process the inner diameter of tank and bearing hole of tank end plate, the high machining precision guarantees gap requirement between mixing blade and tank and prevents particles from grinding during mixing and heating. Temperature measurement is accurate,it adopts new temperature measuring technology to improve temperature measuring performance of thermo-responsive and anti-interference. Perfect air tightness,it adopts combined overlapping metal ring to form multiple sealing to guarantee no carbon powder leakage from shaft end of mixing blade; Hydraulic rotary lock discharge gate has excellent air tightness, sealing surface of which will never wear out that air tightness is reliable with no material leakage from discharge gate. HP-CPK Series Carbon Paste Kneader

High mixing quality, it adopts intersectant, synchronous mixing blade technology from Japan. Mixing blades radius exceed the middle of tank which enlarge actuating area; two mixing blades have the same spiral climbing direction but different rotating direction, one mixing blade pushes material to the middle and the other one pushes to both sides, material flows like “8” in the tank. Introduce in the original mixing blade from Japan, the section of the blade is elliptic which pushes materials to move along with vertical direction of the elliptic section, squeezing action is intensified, material granules are fully mixed, mixing and kneading effect is strengthened. Elliptic section does not stick to material easily and the surface of mixing blades is free of materials.

Post time: Nov-10-2023