– Hwapeng Carbon Electrode Paste Briquetting Machine – Hwapeng

– Hwapeng Carbon Electrode Paste Briquetting Machine – Hwapeng Detail:

1. It changes the problems of difficult breaking of large paste and large impurities in the past;

2. The finished products produced have smooth and beautiful appearance, and are convenient for packaging and transportation;

3. The original integral roller is changed into a movable roller skin to facilitate the replacement and maintenance of the roller skin in the later stage. In addition, according to the different needs of users, it can meet the requirements of different shapes and sizes.

The roller skin of carbon ball press is generally 65Mn casting, and 9 chromium 2 molybdenum or alloy can also be used. The specific situation should be selected according to the actual situation of the material. With the development of carbon technology, the durability and forming rate of carbon ball press are widely concerned. Therefore, the carbon ball press is generally made of 9 CR 2 mo roller skin with strong wear resistance, which will greatly improve the service life of carbon ball press.

| Model | Compression roller diameter | Theoretical productivity | Reducer | Power of electric motor |

| YJ500 | 500mm | 3~5 tons/hour | ZQ500 | 11kw adjustable speed motor |

| YJ650 | 650mm | 5~12 tons/hour | ZQ650 | 15kw adjustable speed motor |

| YJ750 | 750mm | 10~18 tons/hour | ZQ750 | 22kw adjustable speed motor |

| YJ850 | 850mm | 15~25 tons/hour | ZQ850 | 30kw adjustable speed motor |

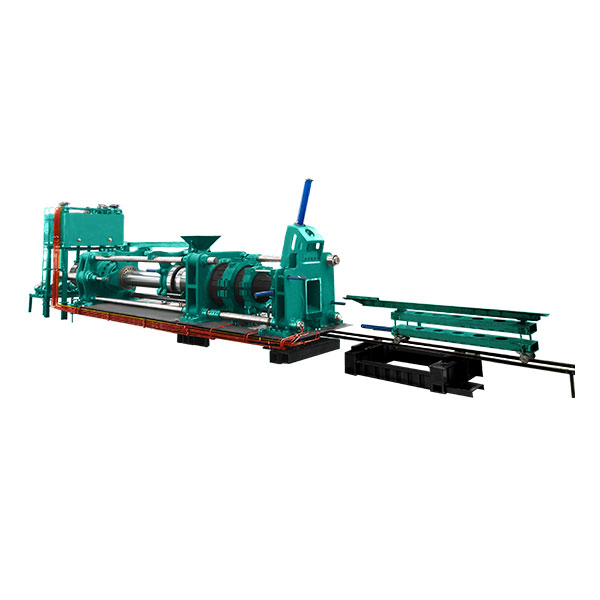

The feeding part is mainly to realize quantitative feeding to ensure that the materials enter the counter roll evenly. The screw feeding device is driven by the electromagnetic speed regulating motor and rotates through the belt pulley and worm reducer to force the pressed material into the main feed inlet. Due to the constant torque characteristic of the electromagnetic speed regulating motor, when the pressing amount of the screw feeder is equal to the material amount required by the host, the constant feeding pressure can be maintained to stabilize the pellet quality. If the feeding amount is too large, the electric overload of the feeding device; If the feeding amount is too small, the ball will not be formed. Therefore, skilled operation skill is an important condition to ensure the normal operation of the pressure ball.

2.The transmission part, the main transmission system is: Motor – triangular belt – reducer – Open Gear – roll. The main engine is powered by an electromagnetic speed regulating motor,

It is transmitted to the driving shaft through the belt pulley and cylindrical gear reducer through the rod pin coupling. The driving shaft and the driven shaft ensure synchronous operation through open gears. A hydraulic device is installed behind the passive bearing seat. The hydraulic protection device is that the high-pressure oil is pumped into the hydraulic cylinder by the hydraulic pump to make the piston produce axial displacement. The front connecting head of the piston rod is on the bearing seat to meet the production pressure requirements.

3.The forming part mainly refers to the host part, and the core part is the roll. When too much material is fed between the two pressure rollers or enters the metal block, the piston rod of the hydraulic cylinder will be overloaded, the hydraulic pump will stop, the accumulator will buffer the pressure change, the overflow valve will open and return oil, and the piston rod will shift to increase the gap between the pressure rollers, so as to make the hard objects pass through the pressure rollers, and the system pressure will return to normal, which can protect the pressure rollers from damage. The machine can adjust the pressure according to the requirements of ball pressing density, and the production is flexible.

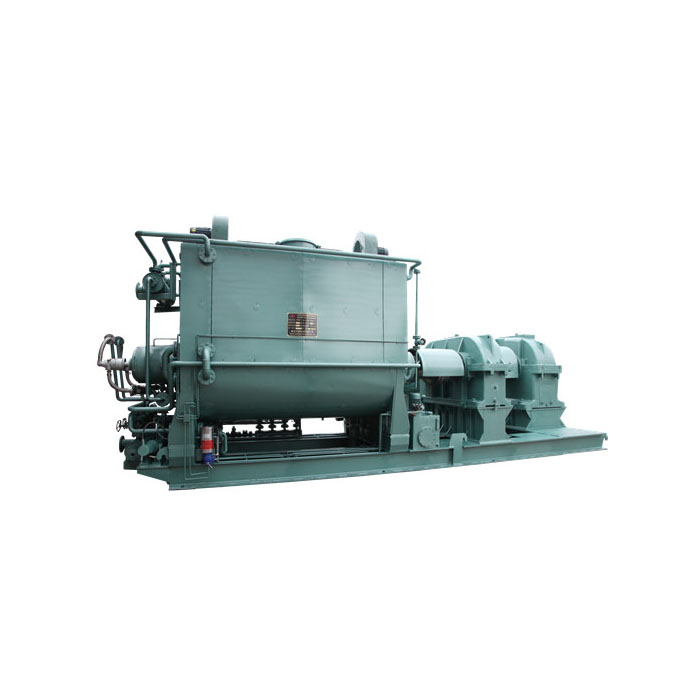

Product detail pictures:

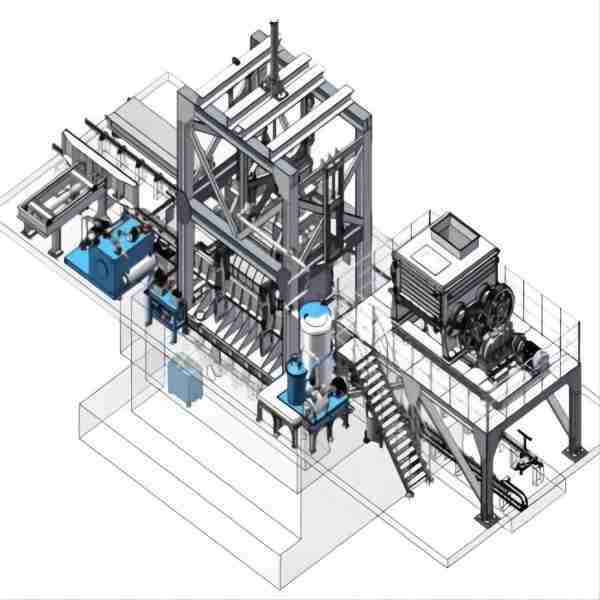

Related Product Guide:

In order to give you convenience and enlarge our business, we also have inspectors in QC Team and assure you our best service and product for – Hwapeng Carbon Electrode Paste Briquetting Machine – Hwapeng , The product will supply to all over the world, such as: Cyprus, Plymouth, Luxembourg, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.