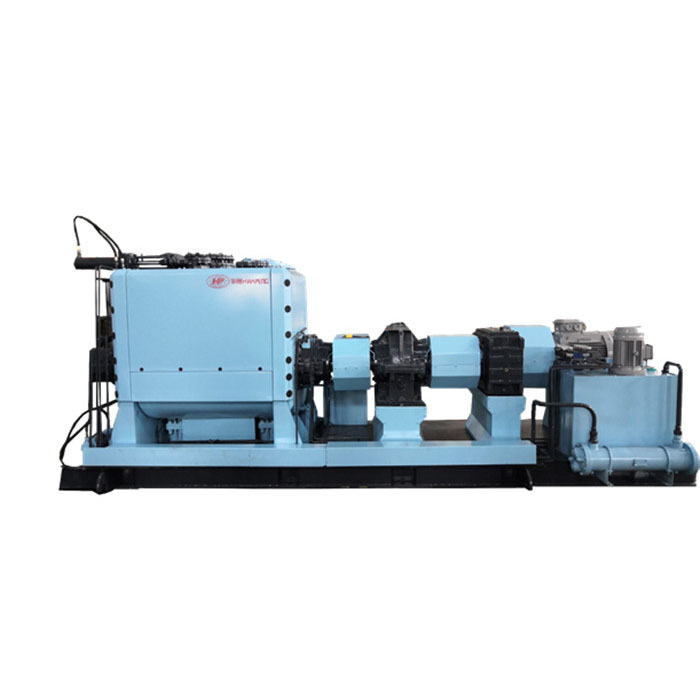

– Hwapeng Hp-Cep Series Carbon Extrusion Press – Hwapeng

– Hwapeng Hp-Cep Series Carbon Extrusion Press – Hwapeng Detail:

HP-CEP Series Carbon Extrusion Press adopts premium hydraulic extrusion and control technology, vacuum technology, piecewise heating technology, synchronous shearing technology, and PC technology and so on to provide the best carbon extrusion solution.

Technical Performance

1. Precise control of extrusion speed

The hydraulic system drives main plunger cylinder to accurately control extrusion speed of graphite electrodes and to ensure quality of graphite electrodes.

2. New die design

The design of multi-curve reducing section combined with short transition section die can greatly improve forming density and surface quality of graphite electrode.

3. Vacuum system

Vacuum system evacuates the paste during both the pre-ex-trusion and extrusion process to fully emit pitch fume and to improve forming and finished product quality, to get short pre-extrusion time and efficient production.

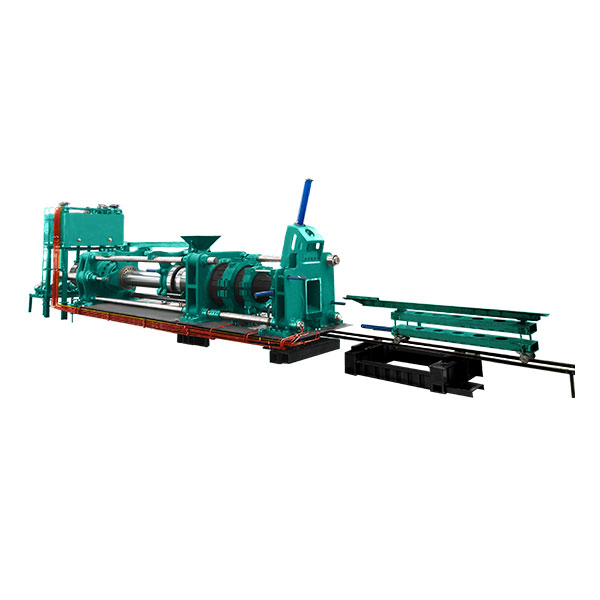

4.Automatic synchronous shearing device

It avoids internal layering, expansion, cracking and other defects of graphite electrodes caused by fixed type shearing device and guarantees quality of graphite electrodes and improves production efficiency.

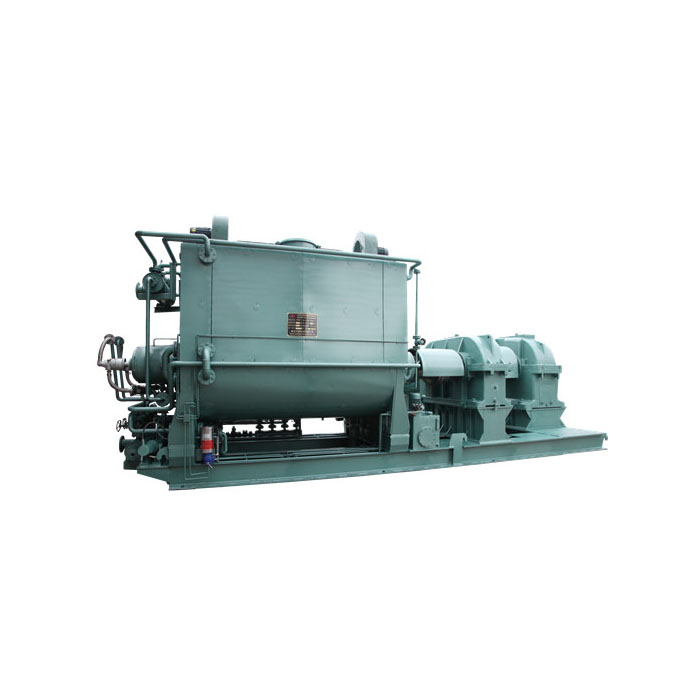

5. Fixed type single material chamber

Simple structure ensures the cost saving of equipment, infra structure and supporting facilities, and reliable operation and easy maintenance.

6. Accurate temperature control of material chamber and die by stages

Material chamber and dies are heated with accurate temperature control by stages to guarantee stable quality of graphite electrode.

7.Quick return assisted by auxiliary cylinder

Auxiliary cylinders are responsible for quick return movement of the extrusion rod to improve work efficiency.

8. Hydraulic control system

Domestic and overseas famous cartridge system, valves and filtering systems and pump station adopting independent circulation system are applied to guarantee continuous stable and reliable operation of hydraulic system. Flanged pipe connection guarantees reliable sealing and zero leakage of hydraulic system pipes under multiple high pressure circulations.

9. PLC automatic control

PLC automatic control is applied to set key process parameters and to automatically control the process, the system runs automatically which guarantees production process parameters and quality stability, productivity is improved and production cost is reduced.

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of – Hwapeng Hp-Cep Series Carbon Extrusion Press – Hwapeng , The product will supply to all over the world, such as: Greece, Dubai, Ukraine, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.