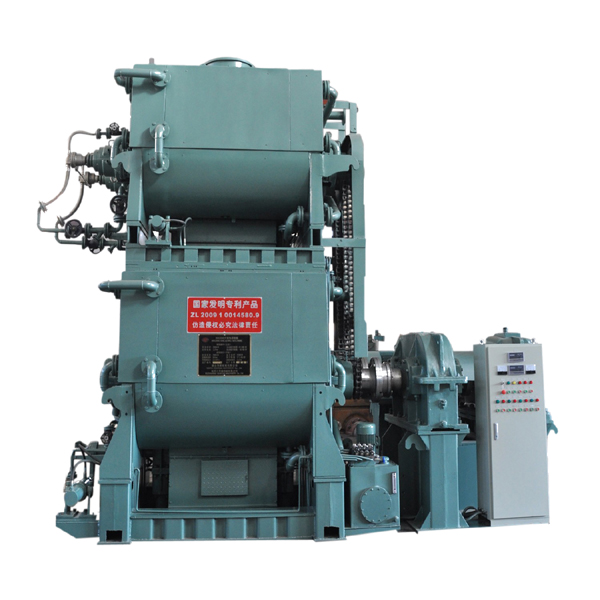

– Hwapeng HP-EPB Series Electrode Paste Forming Machine – Hwapeng

– Hwapeng HP-EPB Series Electrode Paste Forming Machine – Hwapeng Detail:

| No. | Item | Parameters | |

| 1 | Rated Capacity | 2-3T/H | 3.5-4T/H |

| 2 | Power of Main Transmission | 7.5KW | 7.5KW |

| 3 | Model of Reducer | XWED 106-7.5kw | XWED 106-7.5kw |

| 4 | Available Capacity of Thermal Insulation Storage | 3000L | 4000L |

| 5 | Heating Method of Thermal Insulation Storage | Heat Transfer Oil | Heat Transfer Oil |

| 6 | Length of Chain Plate | 15M | 20M |

| 7 | Dimension of Briquette | Upper part 60*60mm/ Bottom Part 50*50mm |

Upper part 120*70mm/ Bottom Part 90*40mm |

| 8 | Pitch of Chain Plate | 60mm | 120mm |

1. Electrode paste forming machine belongs to the mechanical category of paste forming machine in smelting industry. It has the advantages of novel design, reasonable layout, high production efficiency, adjustable speed, convenient operation and so on. The electrode paste products have high strength, low porosity, high temperature resistance, small coefficient of thermal expansion, good appearance and small weight difference.

2. The electrode paste products produced by the electrode paste forming machine have high strength, low porosity, high temperature resistance, small coefficient of thermal expansion, good appearance and small weight difference.

3. The electrode paste forming machine is an automatic production line, which enters the mold through metering, rolls the forming machine, automatically opens the mold after spraying and cooling, falls on the conveyor or finished product vehicle, and automatically restores the original state to enter the next cycle program.

4. The specification and model of electrode paste forming machine can be designed and manufactured according to different needs of customers, and the length of the equipment can be selected according to the size of customers’ site.

It meets the requirements of ferroalloy and calcium carbide industries for the technical properties of electrode paste products such as low resistivity, small coefficient of thermal expansion, small porosity, high mechanical strength, high oxidation resistance and conductivity, and changes the situation that the long-term quality of electrode paste products is low and can not meet the needs of downstream industries.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for – Hwapeng HP-EPB Series Electrode Paste Forming Machine – Hwapeng , The product will supply to all over the world, such as: Saudi Arabia, Austria, Iran, Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.