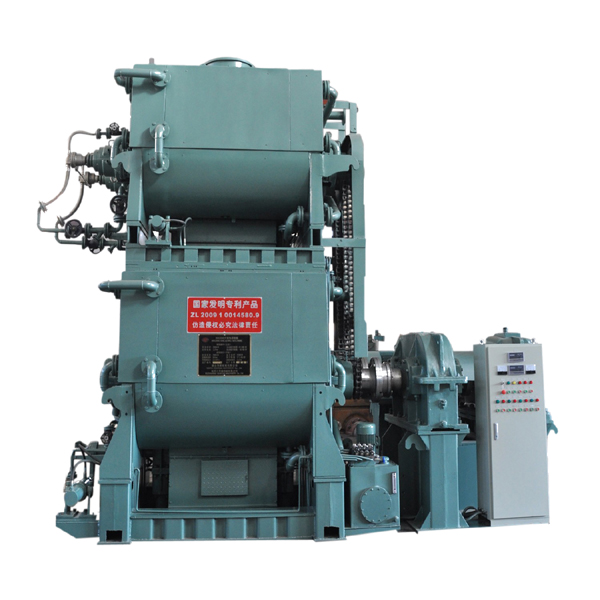

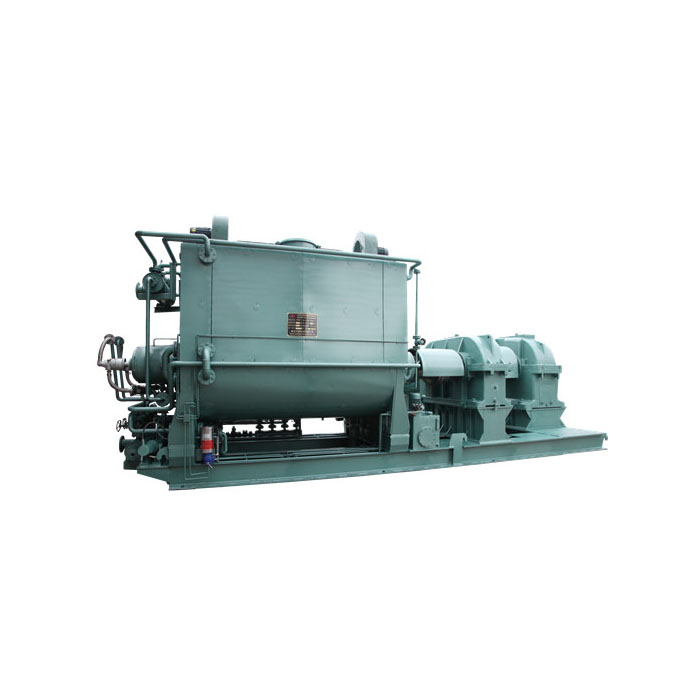

– Hwapeng Hp-Pkc Series Carbon Paste Kneadering Cooler – Hwapeng

– Hwapeng Hp-Pkc Series Carbon Paste Kneadering Cooler – Hwapeng Detail:

1.Low temperature mixing and cooling

Adopt carbon paste cooler technology (Invention Patent NO.: ZL 2012 1 0099062.3), paste cooler technology(patent No.: ZL 2009 2 0273347.8) to knead under low temperature while cooling carbon paste. After carbon paste is kneaded and cooled down to 130℃ (such temperature is related to the features of pitch), with the decrease of temperature, the formation of pitch adsorption layer on aggregate surface is more active, and the layered structure of pitch adsorption layer tends to be arranged in order, which is beneficial to improve the conductivity of carbon products.

2. Molding volume density is improved by 0.02

Carbon product molding and finished product volume density are improved by 0.02 under the same molding condition..

3. Yield is improved by 2-5%

Carbon product defects are eliminated, yield of finished product made by cooled carbon paste is improved by2-5% under the same process condition.

4. Amount of pitch is reduced by 2%

Pitch consumption amount in the previous “mixing” production procedure is reduced by more than 2%.

5. Cooled paste is incompact

The carbon paste cooler technology is adopted by which special designed mixing blades mix and scatter paste powerfully.

6. Cooled carbon paste is of uniform temperature

Carbon paste is mixed and cooled down by circulating cooling medium simultaneously.Two mixing blades rotate synchronously but in opposite direction, so materials flow in order in the tank, which homogenize the paste temperature and property, minimize mixing resistance and save equipment driving power.

7.Cooling efficiency is high

Adopt mixing blade heating technology (patent No.: ZL 2006 20085174.3, mixing blade has cooling medium inside to cool down paste), whole area heating technology (patent No.. ZL20042 0018996.0),intensive heat transmission jacket, material discharge gate cooling and lining plate and tank seam- less-fitting and other cooling-intensifying technology.

8. Pitch smoke completely escape

The specially designed mixing blades scatter the paste constantly to make it incompact escaping of pitch smoke is thus speeded up.

9.Temperature measurement is accurate

Adopt new temperature measuring technology (patent No. ZL2014 2 0490132.2) to improve temperature measuring performance of thermo-responsive and anti-interference.

10. Fast material discharge, no material residue

Mixing blade pushes materials spirally to discharge material fast and completely from bottom open discharge gate in less than 2 min without residue left.

11. High wear resistance

Mixing blade is surface-welded with wear-resistant layers, rigidity of which is up to HR6065, and service life of mixing blade is 20 years. New type wear-resistant manganese steel material is used as lining pate with high strength after thermal treatment. Service life of lining plates for anode production s15 years and 1 year it is for cathode and carbon electrode production.

12. Bearing structure of mixing blade is reliable

Mixing blade shaft adopts self-aligning roller bearing and double-direction thrust bearing design which overcomes axial force of mixing blade and prevents mixing blades from axial shifting and service life of bearing is longer. Bearing structure is fixed on one side and movable on the other side, which eliminates influence of thermal expansion and prevents mixing blade from seizing after it is heated by heat transfer oil.

13. Reliable operation

It adopts hard teeth reduction gearbox and synchronous gear- box split structure with full lubrication and reliable operation. Hard teeth reduction gear, bearing capacity of which is 3 times of common one, together with gear coupling, guarantees high bearing capacity of transmission system. Hydraulic clutch can adjust transmitted torque according to the load to provide overload protection, and allow the machine to restart with load in case of some special conditions (such as restart after stopping during running)

14. Low noise

It is machined by special equipment, to get good concentricity, making the operation smooth, the service life long, and the operation noise of the entire machine less than 80dB.

15. PLC full automatic control

PLC control and internet communication are adopted to measure, display and transmit equipment running and status parameters at real time (optional configuration). Three kinds of operation mode—internet automatic, single machine automatic and manual..guarantee the machine itself can run automatically no matter if upstream and downstream machines are automatic.

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for – Hwapeng Hp-Pkc Series Carbon Paste Kneadering Cooler – Hwapeng , The product will supply to all over the world, such as: Jordan, Greenland, Netherlands, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.