Electrolytic Aluminum Pot Tending Machine

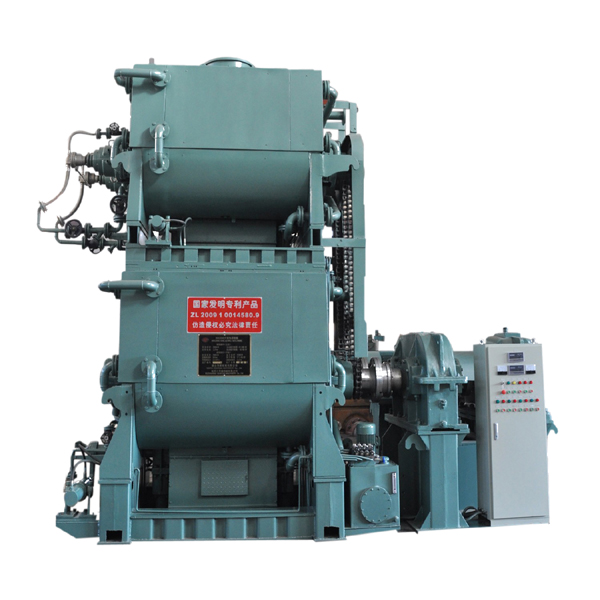

Electrolytic aluminum pot tending machine

The electrolytic aluminum pot tending machine is a key process equipment for the production of large-scale prebaked anode electrolytic aluminum. It can adapt to the special environment of high temperature, large current, strong magnetic field, dusty and HF (hydrogen fluoride) gas. It can complete the following processes at prebaked anode electrolytic cell :

(1) Shelling: Open the electrolyte crust and add electrolytes such as alumina and fluoride salt to the electrolytic cell;

(2) Add materials: add electrolytes such as alumina and fluoride salt to the electrolytic cell;

(3) Replace the anode: unscrew the lifting and lowering to tighten the screw clamp, lift off the residual anode, and replace with a new anode;

(4) Remove the slag: unscrew the lifting and lowering to tighten the screw clamp, lift off the residual anode, and replace with a new anode;

(5) Aluminum tapping: vacuuming, aluminum tapping, lifting and measurement (single package and accumulation) and display, and printing;

(6) Lift the anode busbar and hoist the anode busbar lifting frame;

(7) Maintenance: Complete the installation and maintenance of the electrolytic cell upper structure and lower tank shell and other sporadic lifting.

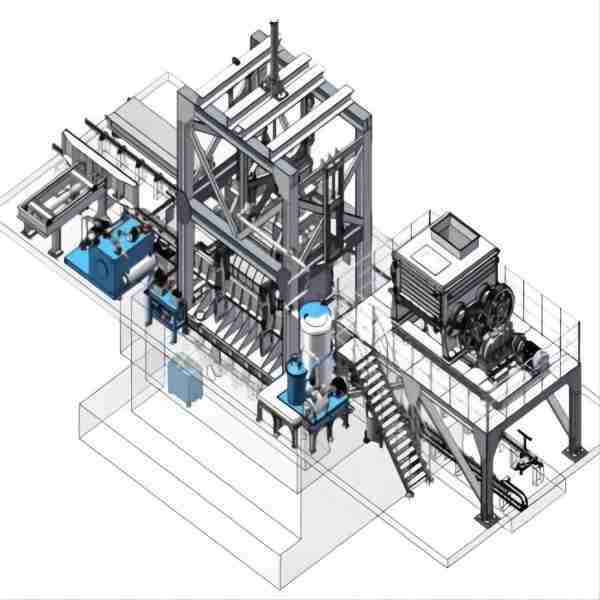

Product Composition

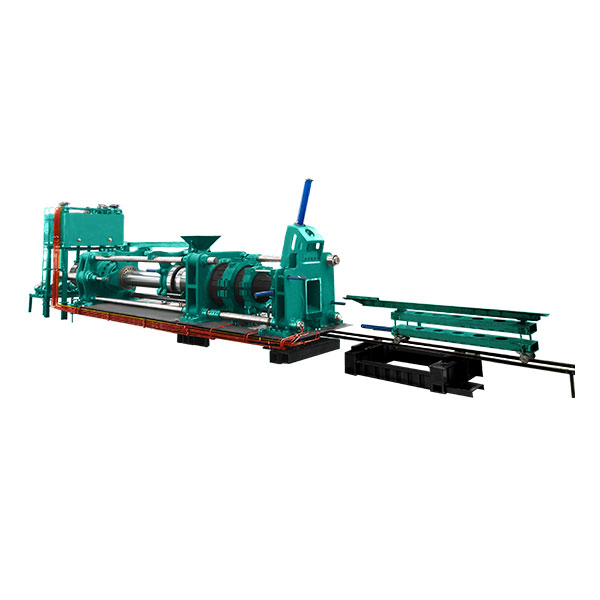

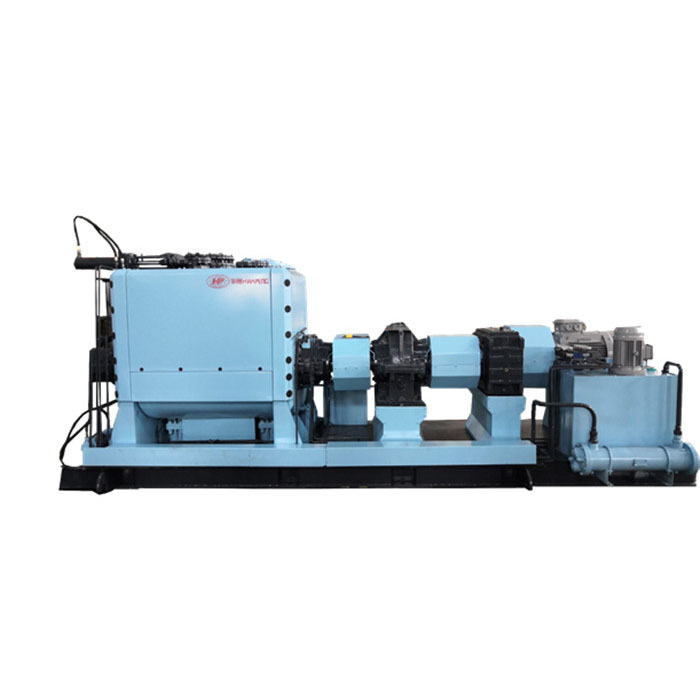

The unit is composed of a cart operating mechanism, a bridge, a tool trolley, an aluminum tapping trolley, hydraulic and pneumatic, and an electronic control system. Its core is the tool trolley, which consists of the trolley operating mechanism, trolley frame, tool rotation mechanism, shelling mechanism, anode replacement mechanism, slag removal mechanism, unloading mechanism, driver's cab rotation mechanism, etc. The whole machine adopts frequency conversion and PLC control. The whole machine is operated by a operation room or a remote control. The two operating modes can cooperate with each other or be controlled independently. This unit has been widely used in the electrolytic aluminum industry and is well received by users.