Suction and Discharge Crane

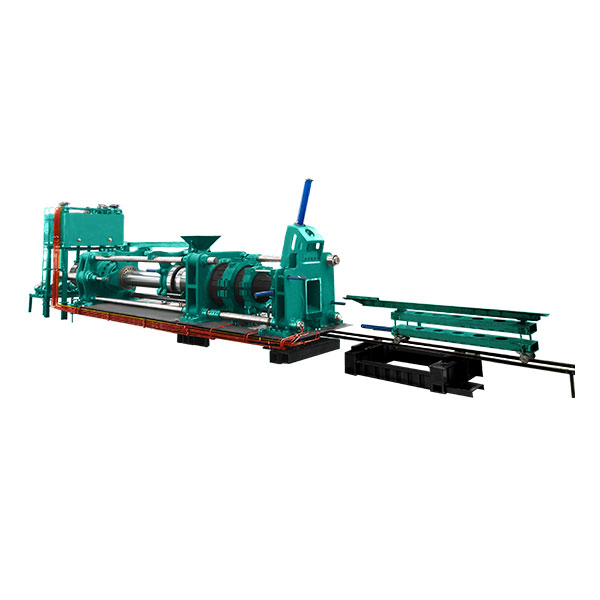

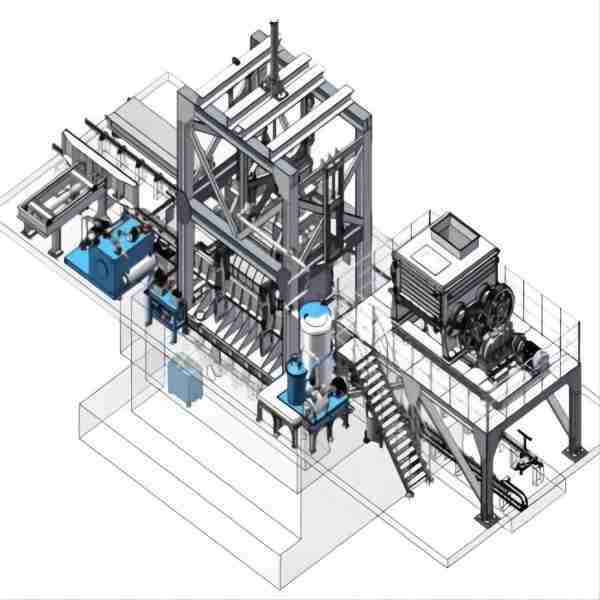

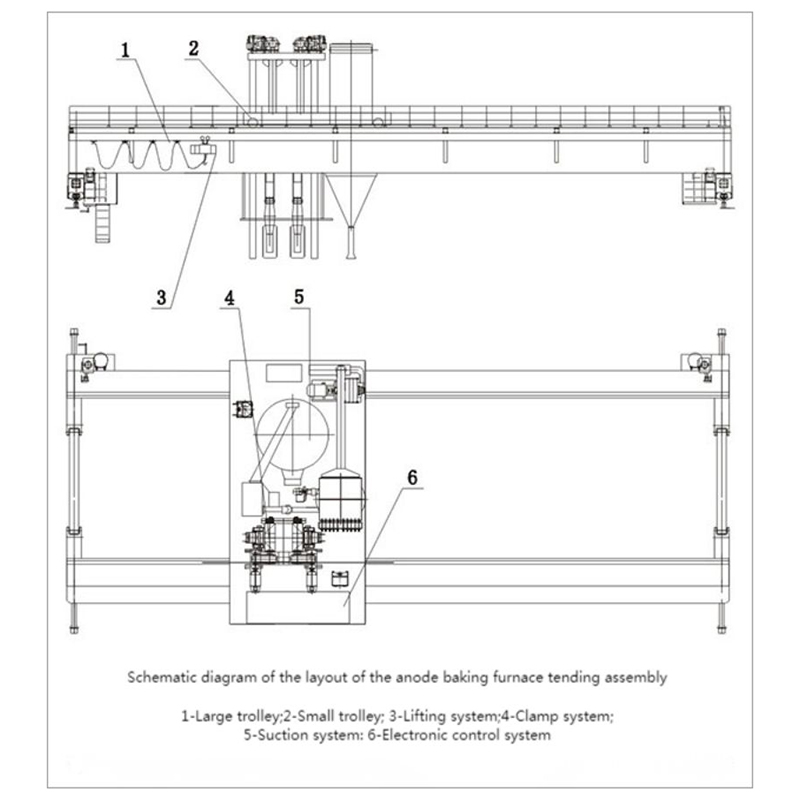

The suction and discharge crane is a special equipment for the baking workshop of carbon, graphite, anode materials and other industries. It mainly consists of six major parts: a bridge, large and small trolley operating mechanism, suction and discharge system, cooling system, dust removal system, and electronic control system.

The main application of the suction and discharge crane:

1. Use the discharge pipe to fill the filling material into the baking furnace pit;

2. Use the suction pipe to suck out the high-temperature filling material from the baking furnace pit and separate the filling material from ash;

3. There is an electric lift under the bridge to assist in lifting.

The whole machine adopts PLC control, frequency conversion speed regulation and other configurations. It has been widely used in major carbon factories in China and has reached international standards. It has greatly improved the harsh working environment, reduced the labor intensity of workers and improved work efficiency.

|

Structure |

Subitem name |

Unit |

Parameter |

|

Whole cart |

Total weight |

t |

70-150 |

| Working level |

A6-A8 |

||

| Total installed power |

kw |

170-300 |

|

|

Large trolley |

Working speed |

m/min |

5-50 |

| Speed control method |

Frequency conversion |

||

| Working level |

M6-M8 |

||

| Span |

m |

22.5-36 |

|

|

Small trolley |

Working speed |

m/min |

3-30 |

| Speed control method |

Frequency conversion |

||

| Working level |

M6-M8 |

||

|

Suction and discharge system |

Lifting speed of suction and discharge pipes |

m/min |

0.8-8 |

| Lifting stroke of suction and discharge pipes |

m |

6-10 |

|

|

Silo |

Silo volume |

m³ |

10-60 |

| Suction and discharge speed |

m³/h |

30-100/65-100 |

|

|

Cooler |

Outlet temperature |

℃ |

≤80 |

| Heat dissipation area |

m³ |

200-600 |

|

| Processing temperature |

℃ |

240-600 |

|

|

Dust removal |

Filter area |

m³ |

60-200 |

| Filter effects |

mg/m³ |

≤15 |

|

|

Centrifugal fan |

Power |

kw |

75-200 |

| Air volume |

m³/min |

75-220 |

|

| Vacuum degree |

KPa |

-35 |

|

|

Compressor |

Pressure |

MPa |

0.8 |

|

Electric hoist |

Lifting volume |

t |

5-10 |

| Lifting speed |

m/min |

7-8 |

|

| Working speed |

m/min |

20 |

|

| Note: The above technical parameters are for reference | |||